Please Choose Your Language

- Polski

- Türkçe

- English

- العربية

- Русский

- Español

- Português

- Français

- Deutsch

- italiano

- 日本語

- 한국어

- Nederlands

- Tiếng Việt

- ไทย

- ភាសាខ្មែរ

- Bahasa Melayu

- Filipino

- Bahasa Indonesia

- magyar

- Română

- Čeština

- Монгол

- қазақ

- Српски

- हिन्दी

- فارسی

- Slovenčina

- Slovenščina

- Norsk

- Svenska

- українська

- Ελληνικά

- Suomi

- Հայերեն

- Dansk

- اردو

- বাংলা

- Hrvatski

- Afrikaans

- Gaeilge

- Oʻzbekcha

- latviešu

- Azərbaycan dili

- Беларуская мова

- Bosanski

- Български

- Esperanto

- ქართული

- Kinyarwanda

- Кыргызча

- Lietuvių

- Oluganda

- Lëtzebuergesch

- Malti

- Wikang Tagalog

- Тоҷикӣ

- Home

- Products

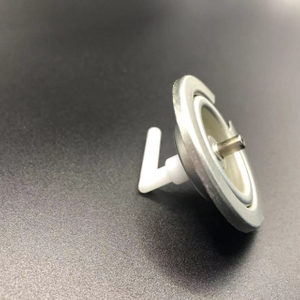

- Continuous Aerosol Valve

- Portable Gas Stove Valve

- All Direction Aerosol Valve

- 20mm Continous Spray Valve

- Air(Room) Freshener Aersol Vavle

- Alcohol Based Insecticide Valve

- Aluminum Aerosol Valve(For Air Freshener)

- Car Care Spray Valve

- Deodorant Spray Valve

- Foam Cleaner Spray Valve

- Inverted Valve

- Lighter Gas Valve

- Oil Based Insecticide Spray Valve

- Paint Spray Valve

- Powder Spray Valve

- Protable Gas Stove Valve

- PU Aerosol Valve

- Ribbon Spray Valve

- Shaving Foam Spray Valve

- Silicon Spray Valve

- Silicon Spray Valve

- Snow Spray Valve

- Carburetor Cleaner Spray Valve

- Hair Spray Valve

- Body Spray Valve

- Metering Aerosol Valve

- Aerosol Cap

- Refrigerant Cap

- Actuator

- Aerosol Bag On Valve

- Aerosol Tinplate Cans

- Female Fire Extinguisher

- Self Defence Papper Spray Valve And Actuator

- Continuous Aerosol Valve

- Hot Products

- Video

- News and Events

- About Us

- FAQ

- Contact Us