Product Description: Our HVLP (High Volume Low Pressure) paint spray valve is designed to deliver fine finishes with high efficiency. This valve utilizes a low-pressure system, which minimizes overspray and waste while maximizing transfer efficiency. The HVLP technology helps achieve smooth and precise coatings, making it ideal for detailed work. With its durable construction, the valve ensures long-lasting performance even in demanding applications. The precision-engineered components ensure consistent paint flow and excellent atomization, resulting in superb, professional-quality finishes. Compatible with a variety of paints and coatings, our HVLP paint spray valve is a reliable choice for achieving outstanding results.

Bullet Points:

- HVLP paint spray valve for fine finishes with high efficiency

- Utilizes a low-pressure system to minimize overspray and waste

- Maximizes transfer efficiency for economical coating application

- Ideal for detailed work requiring smooth and precise coatings

- Durable construction for long-lasting performance

- Precision-engineered components for consistent paint flow and atomization

- Compatible with various paints and coatings

- Suitable for professional painters, craftsmen, and DIY enthusiasts

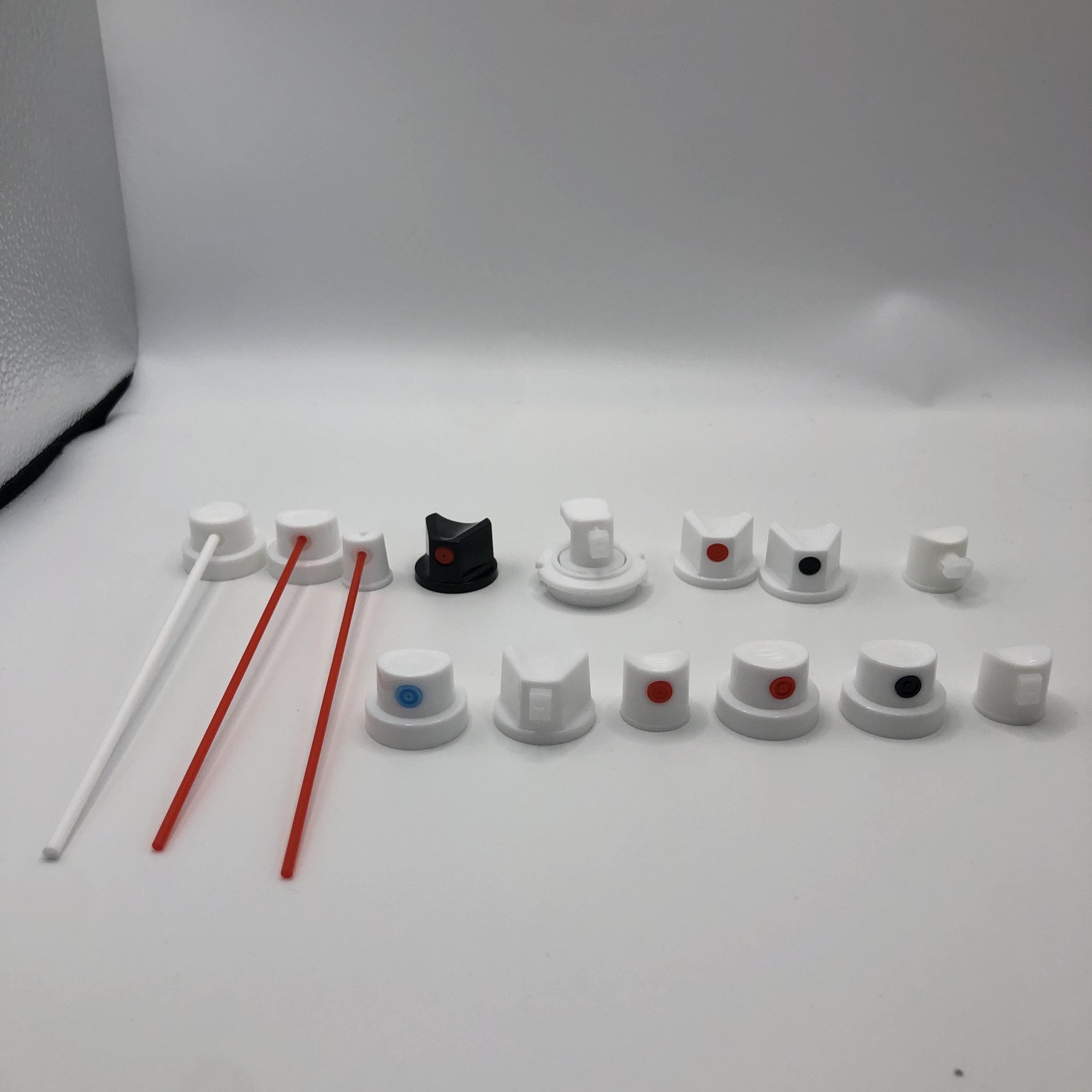

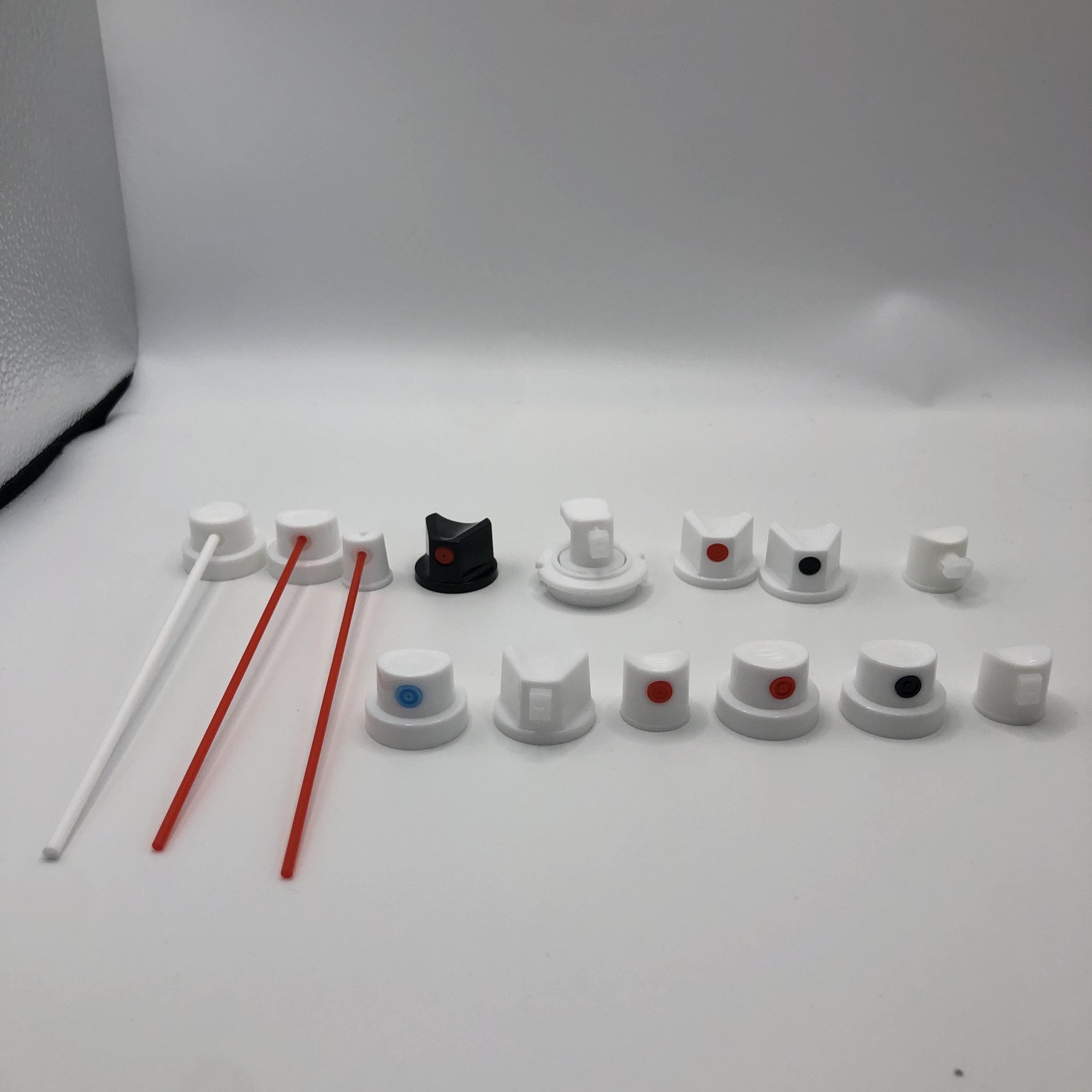

| Component | Part Description |

| Mounting cup | Both sides with clear lacquered tinplate ,with down dimples |

| Outer gasket | Buna |

| Inner gasket | Butyl |

| Stem | single orifice 1*0.51mm natural |

| Spring | Stainless steel |

| Housing | tail orifice Dia 2*0.33mm orange |

| Dip tube | standard natural color |

Specific Application Scenario: Perfect for professional painters, craftsmen, DIY enthusiasts, woodworking projects, fine arts, and applications that require detailed and precise coatings.

FAQ:

Q: What are the advantages of using an HVLP paint spray valve?

A: HVLP technology offers several advantages. By utilizing a low-pressure system, it significantly reduces overspray and waste, making it more environmentally friendly and cost-effective. HVLP paint spray valves provide excellent transfer efficiency, resulting in smooth and precise coatings ideal for detailed work. They also offer better control and are often preferred for achieving fine finishes.

Q: Can I use this HVLP paint spray valve with different types of paint?

A: Yes, this HVLP paint spray valve is compatible with a variety of paints and coatings, including water-based and solvent-based formulations, lacquers, stains, varnishes, and more. It provides versatility for different coating applications.

Q: Is this valve suitable for large-scale projects?

A: While HVLP paint spray valves are commonly used for detailed work and smaller projects, they can also be used for larger-scale projects. However, for extensive coverage, it may take longer compared to high-pressure systems. HVLP valves are often preferred for their precision and fine finish capabilities.

Q: Do I need a specific spraying equipment for this valve?

A: Yes, HVLP paint spray valves are designed to be used with HVLP spraying equipment. This includes HVLP spray guns and turbine systems that provide the appropriate air volume and pressure for optimal operation. It's important to ensure compatibility between the valve and the spraying equipment you intend to use.

Q: How do I clean and maintain the HVLP paint spray valve?

A: Proper cleaning and maintenance are crucial for optimal performance. After each use, clean the valve thoroughly by flushing it with an appropriate cleaning solution or water. Pay attention to the internal components and remove any paint residue or blockages. Regularly inspect and replace worn or damaged parts as needed. Always follow the manufacturer's instructions for maintenance guidelines specific to your HVLP paint spray valve.