Product Description:

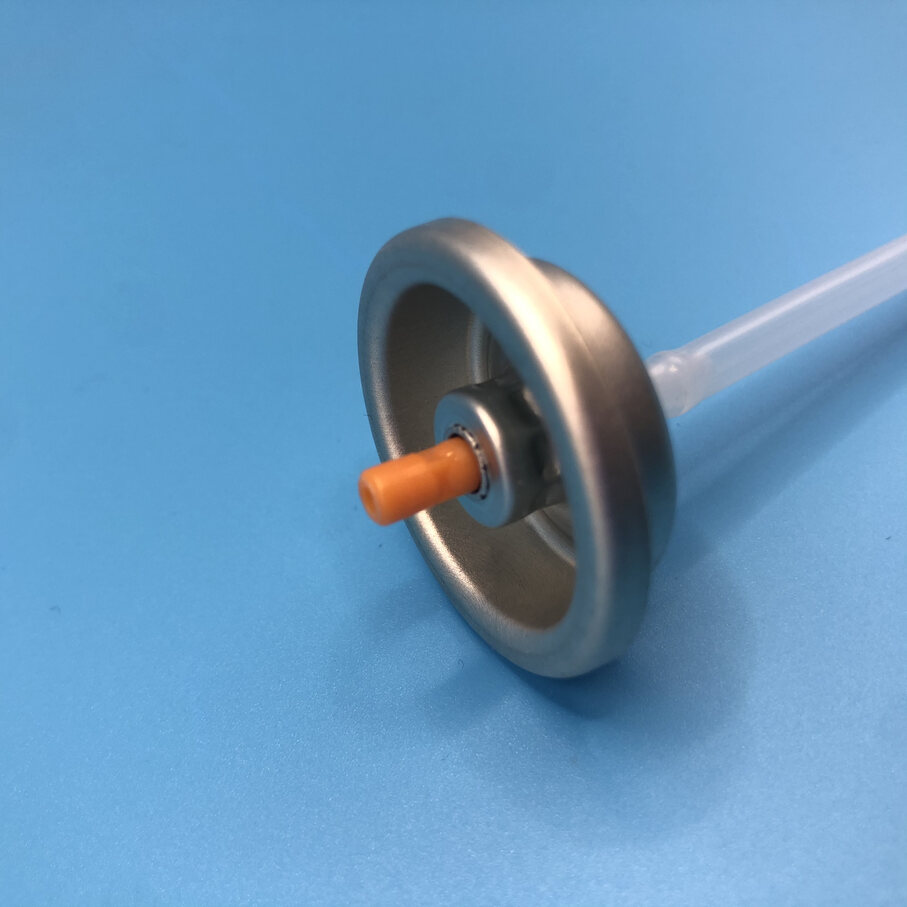

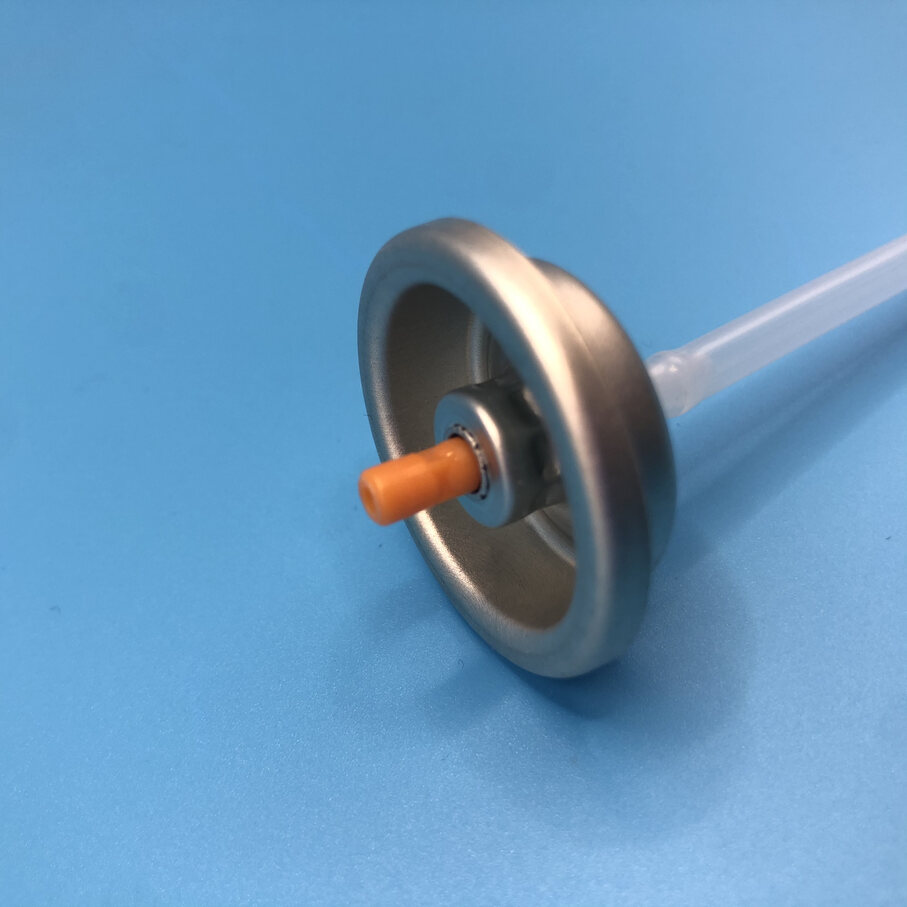

The MDF Kit Activator Valve is a reliable and efficient dispensing solution designed for a variety of applications. It features a plain tinplate mounting cup with down dimples, ensuring secure attachment and minimal leakage. The outer gasket is made of Buna, while the inner gasket is Neoprene (N-205), providing excellent sealing properties. The stem is a double orifice design with two orange-colored orifices, each measuring 0.020" (0.51mm) in diameter, allowing for precise and controlled dispensing. The valve incorporates a stainless steel spring, ensuring smooth actuation and reliable performance. The housing is equipped with a tail orifice measuring 0.080" (2.00mm) in diameter, providing optimal flow characteristics. Additionally, the valve includes a standard dip tube made of natural material. Count on the MDF Kit Activator Valve for consistent and dependable dispensing.

Bullet Points:

Secure attachment with plain tinplate mounting cup with down dimples

Excellent sealing properties with Buna outer gasket and Neoprene (N-205) inner gasket

Double orifice stem with two orange-colored orifices measuring 0.020" (0.51mm) in diameter

Smooth actuation thanks to the stainless steel spring

Optimal flow characteristics with a tail orifice measuring 0.080" (2.00mm) in diameter

MDF adhesive catalyst dispenser valve

Fiberboard curing agent aerosol valve

MDF bonding agent activator valve

Specific Application Scenario:

The MDF Kit Activator Valve is suitable for various industries, including automotive, electronics, and household products. It is ideal for dispensing adhesives, sealants, lubricants, and other fluid materials with precision and control.

FAQ:

Q: Can the MDF Kit Activator Valve be used with high-temperature adhesives?

A: The MDF Kit Activator Valve is generally compatible with a wide range of adhesives, including some high-temperature formulations. However, it is recommended to consult with the valve manufacturer or supplier to ensure the valve's material compatibility with your specific high-temperature adhesive. They can provide guidance on suitable materials and any necessary modifications to the valve to ensure optimal performance and longevity under high-temperature conditions.

Q: Can the MDF Kit Activator Valve be used with solvent-based sealants?

A: Yes, the MDF Kit Activator Valve is designed to work with various sealant formulations, including solvent-based options. The Buna outer gasket and Neoprene (N-205) inner gasket offer excellent compatibility with a wide range of chemicals and solvents. However, it is always recommended to consult with the sealant manufacturer or valve supplier to ensure compatibility and to verify any specific requirements or recommendations for solvent-based sealants.

Q: Is the MDF Kit Activator Valve suitable for use with high-viscosity materials?

A: The MDF Kit Activator Valve is designed to handle different viscosities, including certain high-viscosity materials. The double orifice stem and precise design of the valve allow for controlled dispensing of various fluid viscosities. However, it is important to consider the specific product requirements and consult with the valve manufacturer or supplier to ensure compatibility and optimal performance with your desired high-viscosity material. They can provide guidance on suitable modifications or alternative valve options, if needed, to accommodate specific viscosity requirements.