Durable Bag-on-Valve for Industrial Lubricants with Precision Application and Extended Shelf Life

Product Description:

Our bag-on-valve (BoV) system is engineered for industrial lubricants, offering precision application and extended shelf life. This advanced packaging solution ensures that lubricants such as oils, greases, and anti-corrosion agents are dispensed accurately, enhancing equipment performance and longevity.

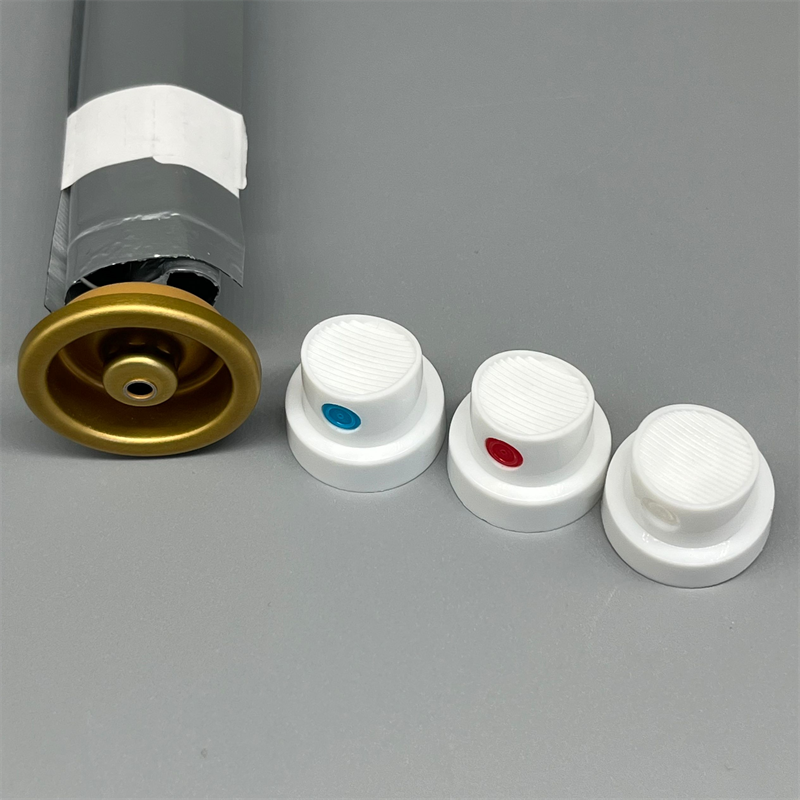

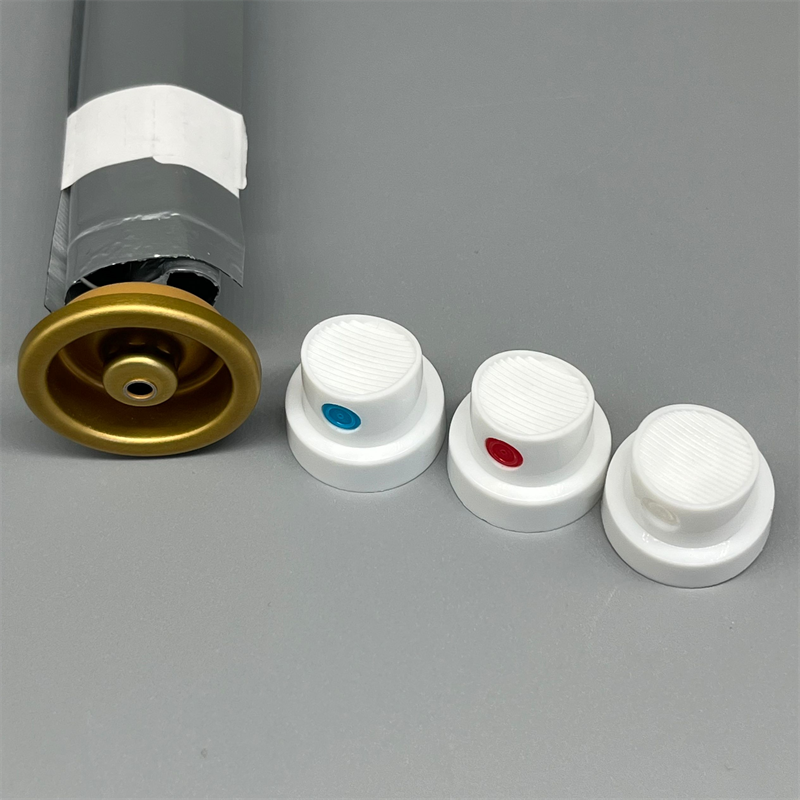

The BoV system comprises a bag affixed to a valve, separating the lubricant from the propellant. This design maintains the purity and effectiveness of the lubricant throughout its shelf life. By utilizing compressed air or nitrogen as the propellant, the system eliminates the risk of chemical interactions, preserving the lubricant's integrity.

One of the key advantages of our BoV system is its ability to deliver consistent and precise application, which is crucial for maintaining equipment efficiency and reducing downtime. The system also allows for 360-degree dispensing, enabling technicians to apply lubricants at any angle, enhancing convenience and accessibility.

Additionally, the BoV system ensures nearly complete product evacuation, meaning industries can utilize the full amount of lubricant without waste. The absence of flammable propellants enhances safety during storage and use, making it a reliable choice for industrial applications.

By integrating our bag-on-valve system into industrial lubricant packaging, companies can ensure the delivery of high-quality, effective, and user-friendly products to maintenance teams.

Bullet Points:

Precision Application: Ensures accurate and controlled lubricant dispensing.

Extended Shelf Life: Maintains lubricant integrity by separating it from the propellant.

360-Degree Dispensing: Allows application at any angle for maximum convenience.

High Product Utilization: Ensures nearly complete lubricant usage, minimizing waste.

Enhanced Safety: Free from flammable propellants, ensuring safe storage and use.

Specific Application Scenario:

Ideal for packaging industrial lubricants used in machinery maintenance, automotive servicing, and equipment preservation, ensuring efficient and precise application.

FAQ:

Q: How does the bag-on-valve system benefit industrial lubricants?A: The BoV system offers precision application, extended shelf life, and maintains lubricant integrity by separating it from the propellant.

Q: Is the bag-on-valve system environmentally friendly?A: Yes, it uses compressed air or nitrogen as propellants, eliminating the need for harmful hydrocarbons and reducing environmental impact.

Q: Can the bag-on-valve system be used with all industrial lubricants?A: The BoV system is compatible with a wide range of lubricant formulations, including oils, greases, and anti-corrosion agents.

Q: What is the product evacuation rate of the bag-on-valve system?A: The BoV system ensures nearly complete product evacuation, minimizing waste.

Q: Is the bag-on-valve system safe for industrial environments?A: Yes, it is free from flammable propellants, offering enhanced safety during storage and use.